Tao, Wenjin

Staff Product Manager @ Bright Machines

Bridging Automation, Robotics, and AI to Build the Next Generation of Manufacturing

What I Build

Field Robotics

A modular, zero-emission robot platform with self-driving capabilities and tool attachments such as lawn mowers, snow plows, and weed controllers. Designed for cost-effective, sustainable outdoor labor.

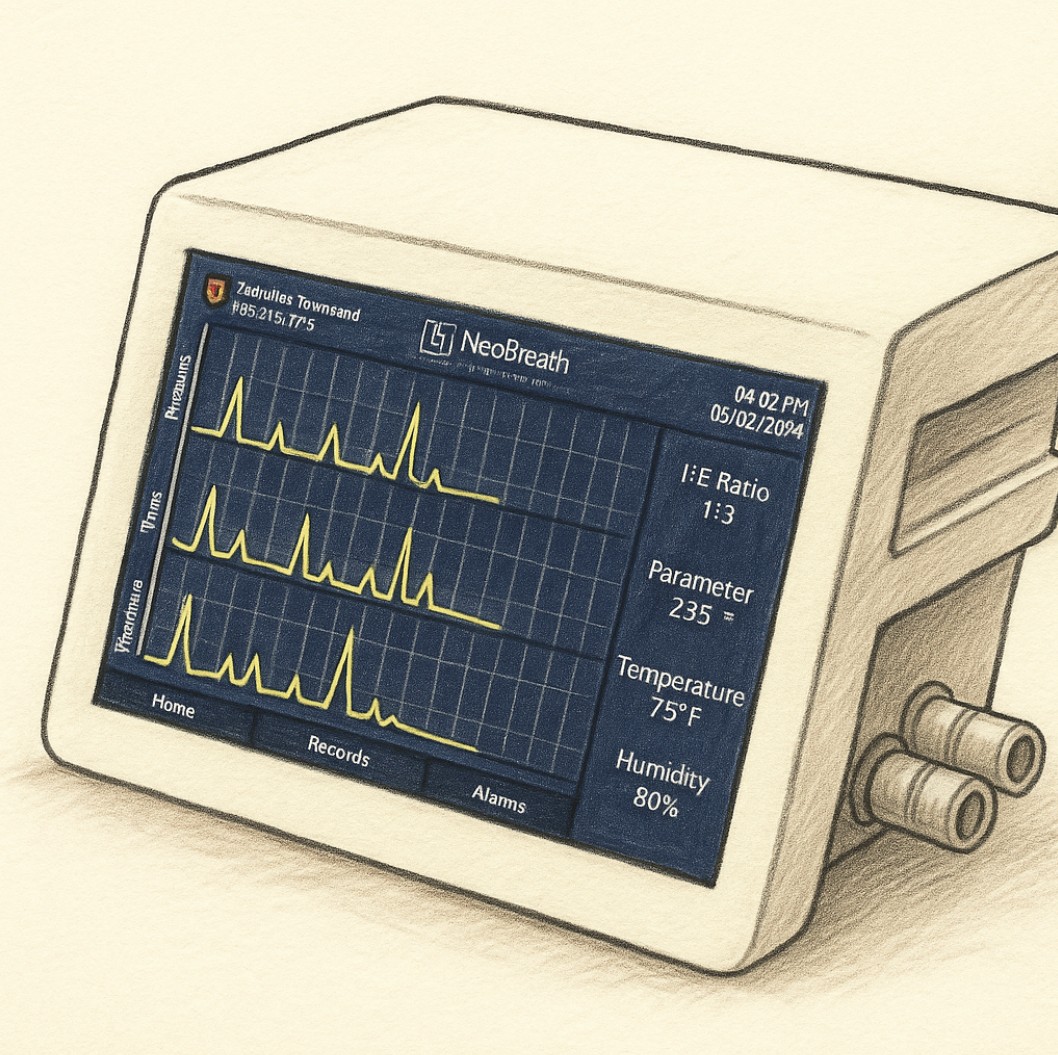

Low-Cost Ventilator Prototype

Designed to be built with off-the-shelf and 3D-printed parts, this ventilator supports emergency medical needs while demonstrating the team's rapid-response engineering and future AI integration potential.

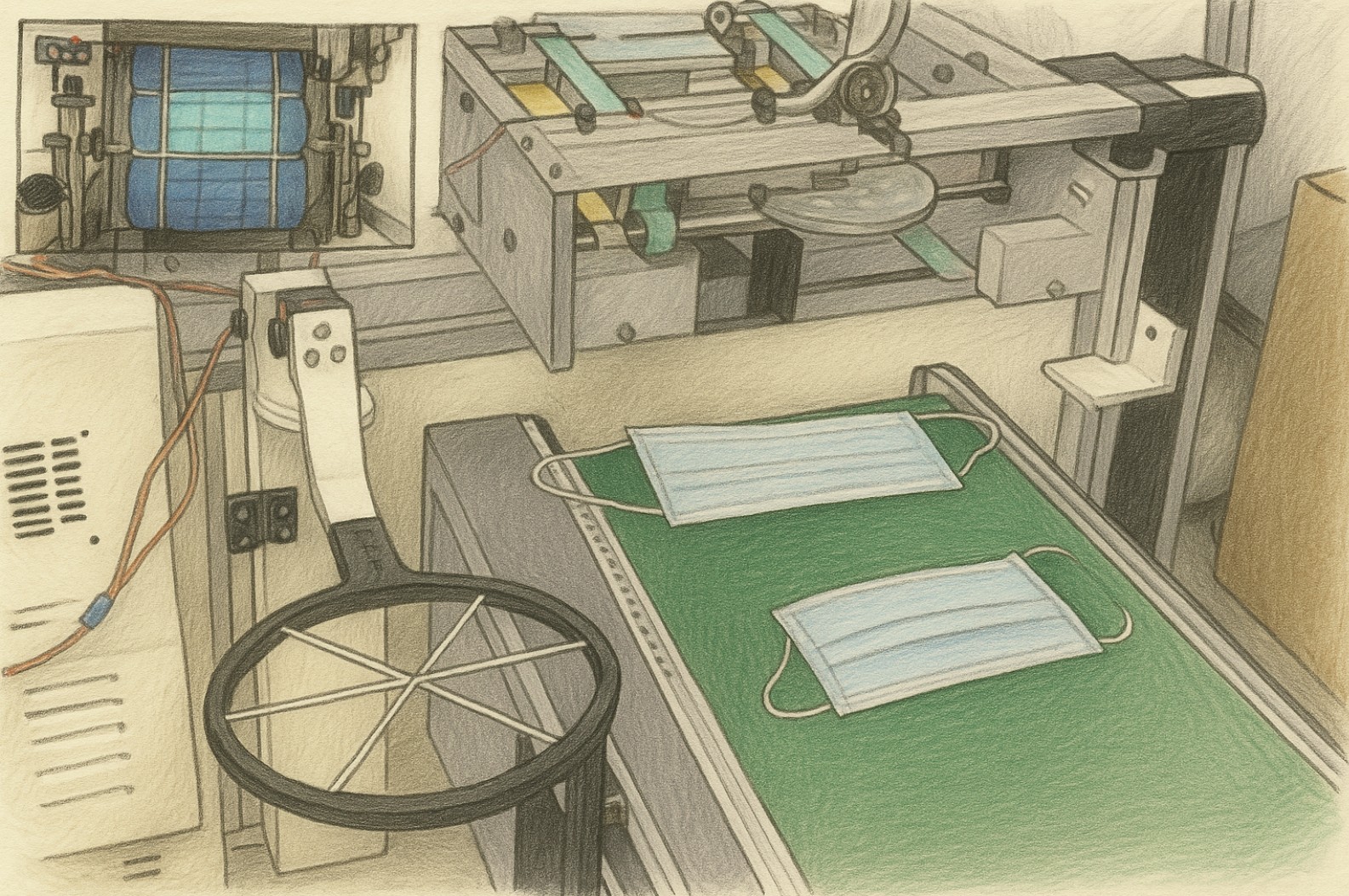

Mask Defect Detection System

Uses image processing and machine learning to detect manufacturing defects in face masks and automatically sort them, improving quality assurance and traceability.

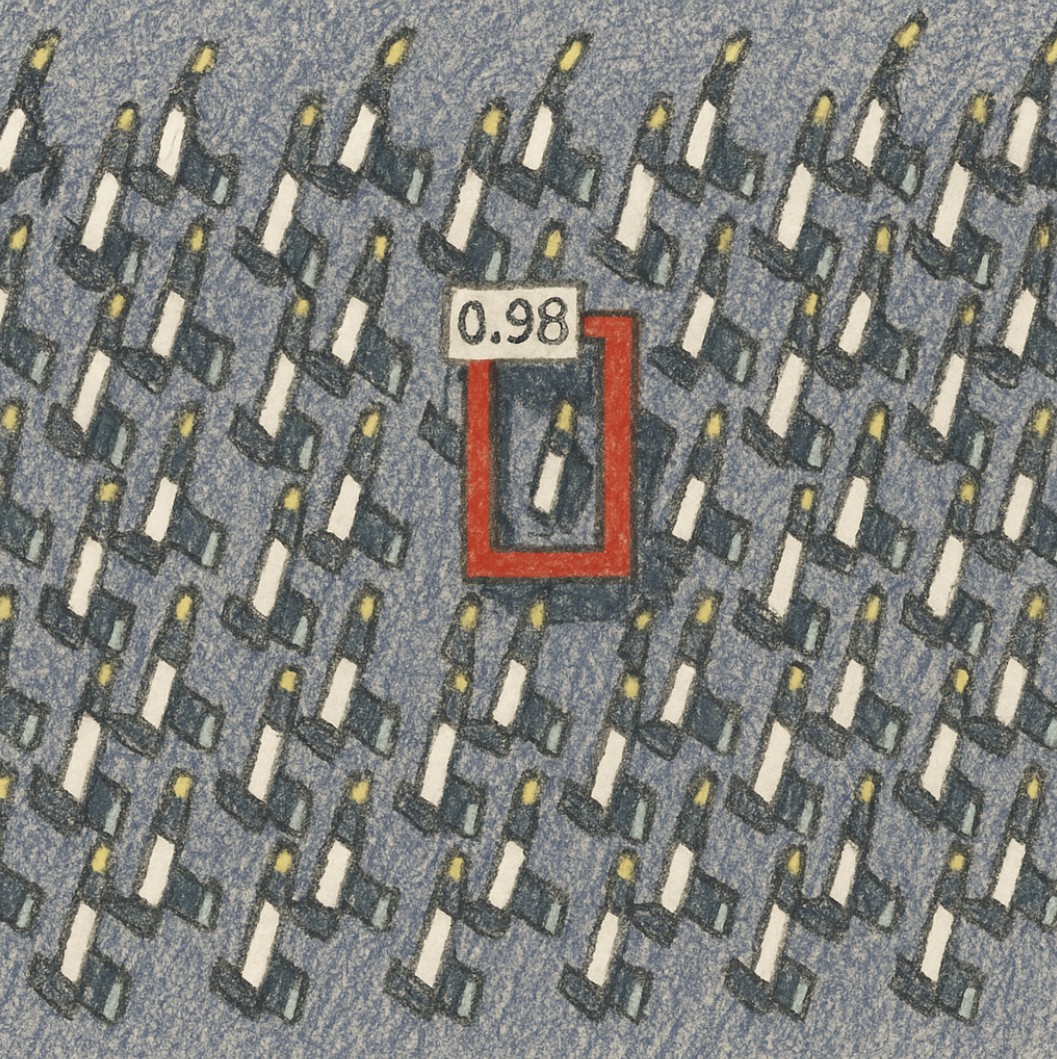

Pin Defect Detection System

Automatically identifies bent or damaged pins in dense electronic components using AI, helping quality teams detect issues early and improve yield.

FOLO: Smart Work Instruction System

Engineers build digital SOPs via drag-and-drop, while operators follow guided workflows. FOLO records production data and supports hardware integration.

OPTIMO: AI-Driven Human Operation Analytics

Streams and analyzes IP camera feeds for time-motion analysis and AI training. Features dashboards for performance insights and industrial process optimization.

Thoughts & Threads

Website Update: New Look, New Content Coming!

June 06, 2025

Bio

I'm a Staff Product Manager at Bright Machines, building intelligent automation solutions that blend robotics, computer vision, and AI to improve factory outcomes. I partner with engineering and operations to shape product roadmaps, ship proof-of-concept deployments, and scale systems that make manufacturing more flexible, data-driven, and reliable. Previously, I led intelligent manufacturing products at Foxconn Industrial AI, driving Industry 4.0 initiatives across global factories.

I hold a Ph.D. in Mechanical Engineering from Missouri University of Science and Technology, where I researched worker-centered intelligent manufacturing with Prof. Ming C. Leu. My work combined deep learning with multimodal sensor fusion (IMU, sEMG, and computer vision) for real-time human activity recognition and process optimization, resulting in more than a dozen peer-reviewed papers and book contributions.